Commitment to investment

The company is committed to a programme of growth and investment in people and the acquisition of the latest technology to remain at the forefront of wire forming technology.

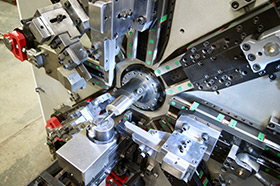

Recent capital investment includes a KCT 1360W2 CNC wire forming machine, which is fulfilling the increased demand for custom wire forms.

This new machine can form wire diameter range of up to 6mm for hard drawn wire and up to 8mm for soft drawn or annealed wire. It has enable Longcroft to extend the range of its offer and complements our existing range of Wafios and HCT CNC spring coiling and wire forming machines.

Other new capital acquisitions include a Fibre Laser Cutter, which can cut complex flat springs and sheet metal components up to 3mm thickness enabling Longcroft to increase capacity and product range and to offer a laser cut components; and an additional stress relieving/spring tempering oven.

Longcroft is also installing an IPC LS1390 Fibre metal cutter machine. This new laser cutting machine can cut flat springs and metal parts of up to 3mm thickness. It’s enabling Longcroft to increase capacity and product range and to offer laser cut components.

Alec Becconsall, Managing Director said, ‘We are delighted with this new addition to our comprehensive range of spring and wire form manufacturing equipment, which will enable Longcroft to provide a cost-effective service for manufacturing components with complex shapes and supports our continuous business development and commitment to expanding Longcroft’s capacity and product range’.